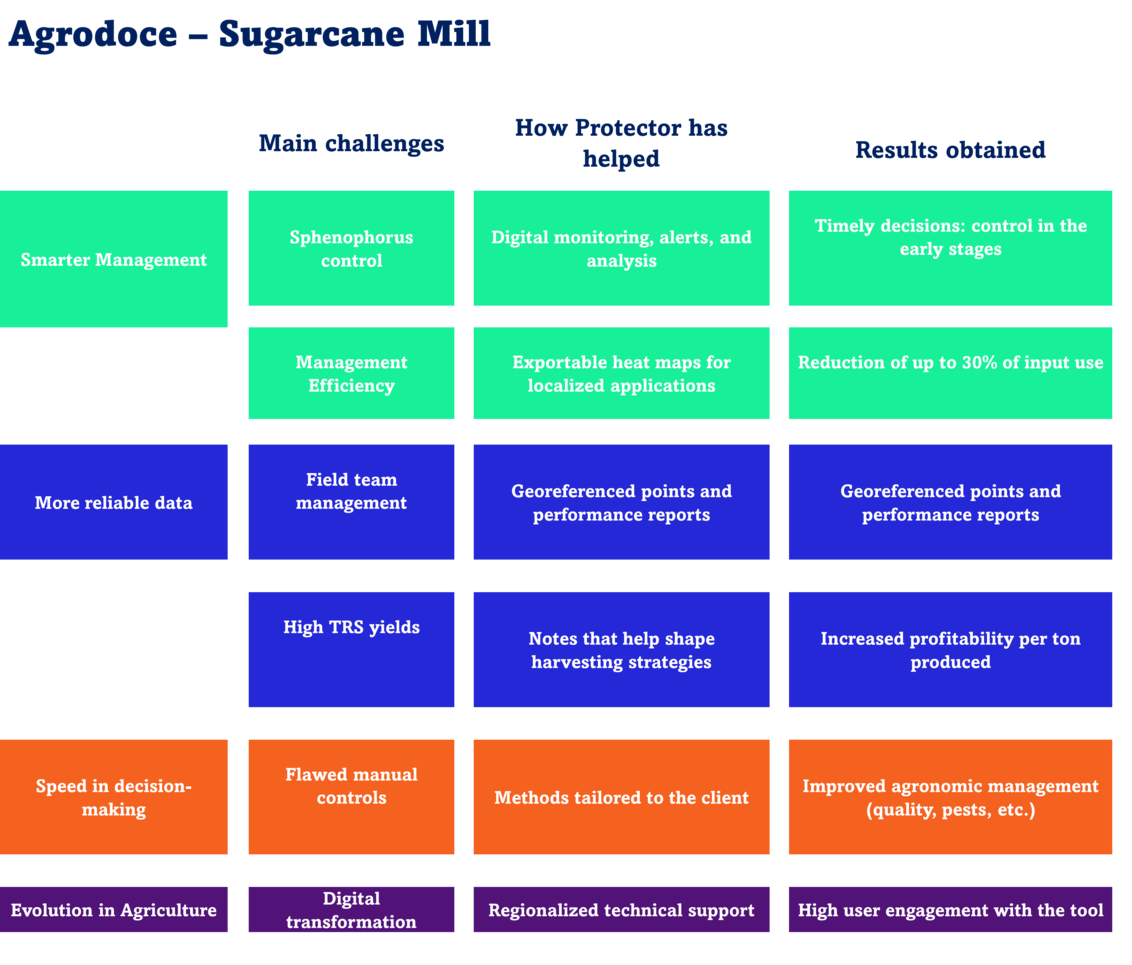

By using Syngenta Digital precision farming solutions, Agrodoce can save around 30% on sugarcane yields per harvest.

Producing more and providing better quality has been a constant pursuit at Agrícola Agrodoce. Producers of 10,000 hectares of sugar cane in Pederneiras, in the state of São Paulo, the group found technology as a way of increasing efficiency and simplifying processes.

Digital farming can now be found at every stage of sugarcane production.

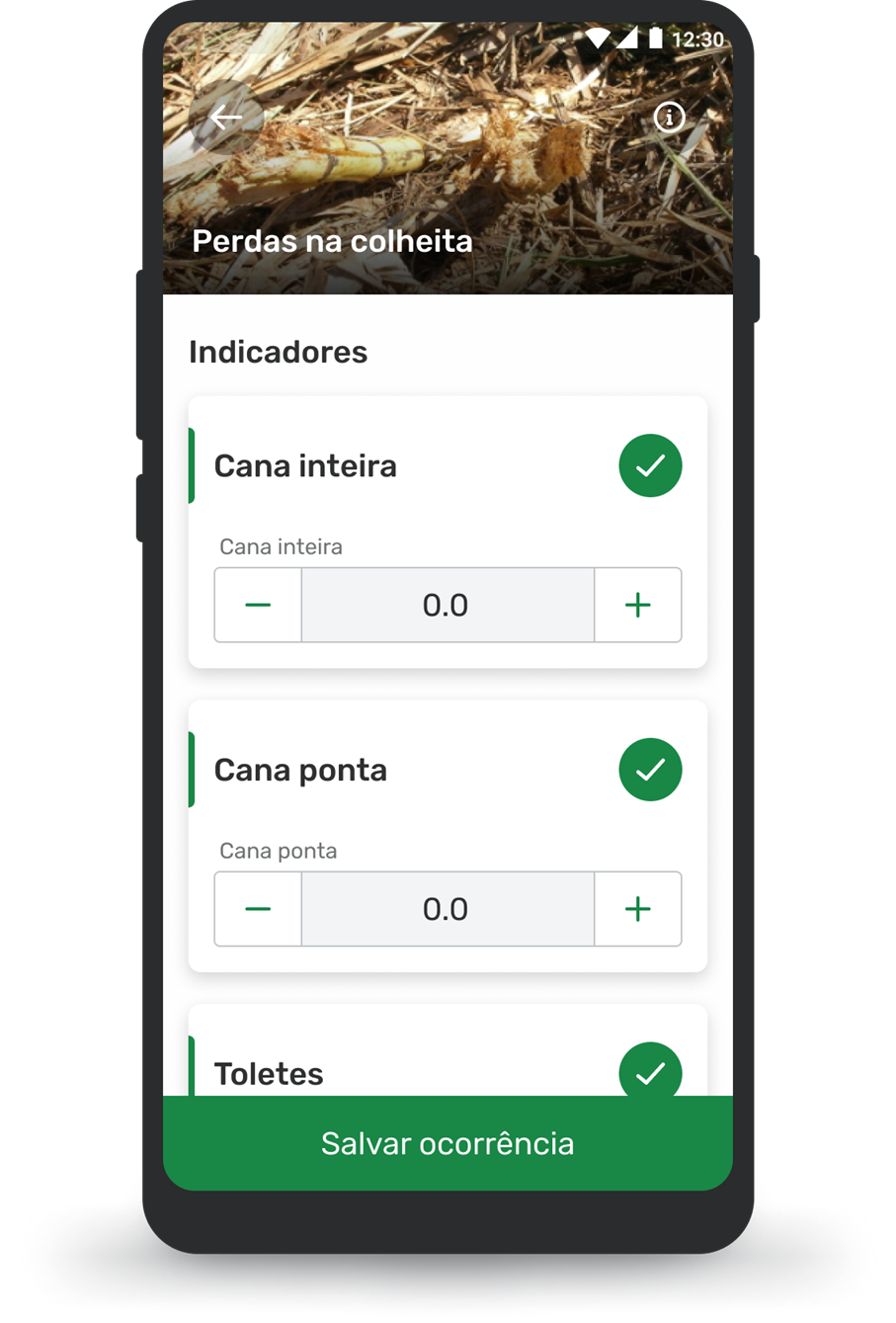

"We use technology for everything, not just monitoring against pests and diseases. Planting, soil, and the harvest are all constantly being analyzed. We monitor loss control and harvest quality. The outcome is what we and everyone else is striving for: productivity gains, cost reductions, and improved quality. It has been a huge help!" says Guilherme Gouvêa de Oliveira, owner of Agrodoce.

From paper to precision farming

However, anyone who sees all this technology incorporated from end to end on the farm, including machines with autopilot and on-board computers, has no idea that the biggest digital transformation actually occurred just under five years ago.

"Our records were still being written up by hand. We were tired of paper, of trying to understand what was written on the countless field sheets. Comparing harvests and crops was very difficult," says Guilherme, who saw what he needed in Protector, which is one of the solutions provided by Syngenta Digital.

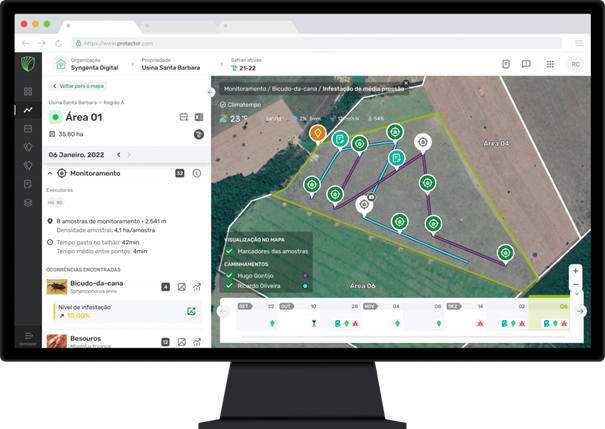

"The tool is very simple and self-explanatory. It has added real value, not just because it helped us digitize our records. The software has also helped us with team management. For example, by using georeferencing, I am able to keep track of staff movements in the daily reports I receive. Before, people could write anything in their notes and say that they had done their monitoring properly, and no one would know. The information we receive is more reliable, it even comes with photos to back it up, which helps me to make the right decisions quickly," he says.

And one result leads to another. Increased monitoring in the field has made it possible to combat Sphenophorus, a common crop pest that appears frequently in the Pederneiras region.

Localized application on sugarcane plantations

Constant monitoring combined with heat map analysis has made it possible to implement localized applications.

"Before, we worked with averages and applied them over the entire field. With the georeferenced points, I know exactly where the pest is and we've been able to prioritize localized spraying," says César, who points out that precision farming has enabled Agrodoce to save around 30% on inputs.

According to Mariana Lobato, Product Marketing Manager at Syngenta Digital, "Using Protector's Heat Map, growers understand the distribution of infestations in their fields and are able to generate specific management zones. This makes it possible to make more informed decisions about applications – such as choosing the most appropriate approach for the pest in question. As well as reducing spreading areas and saving on inputs, super-efficient control can also be achieved."

Digital farming and sugarcane quality

Agrodoce produces 600,000 tons of sugarcane per harvest. As suppliers of raw materials to sugarcane mills, the group faces the constant challenge of maintaining high levels of total recoverable sugars (TRS) in its crop. TRS is a quality indicator that has a direct impact on the value of the sugarcane being sold.

By incorporating digital farming methods into process control, Agrodoce has been able to map out an efficient harvesting strategy, enabling greater profitability per ton produced. The team's time has also been optimized since, by using Protector, technicians are able to take five times as many samples in the same period.

Advances in sugarcane technology

Agrodoce was one of Syngenta Digital's first sugarcane customers. They have been using Protector in their operations since 2017 and have followed the tool's evolution closely over time.

"Many improvements have been made from the first version to the one we're running. It's faster, it has more features, and the dashboard display is better. In the blink of an eye, you can spot exactly where the pest is," says César.

Interaction with Syngenta Digital has also changed. Digital Transformation Specialist, Matheus Camilo, is now working with Agrodoce in the region.

"Having a permanent contact from Syngenta Digital closer to our operations is very important. Camilo is always there, helping us to improve," says the company owner.

And that really is the whole purpose of a digital transformation specialist: adding value through technology and helping producers solve challenges in the field.

The partnership has really paid off.

Agrodoce has just implemented eight weather stations that will track the amount of rain, humidity, and wind in planted areas. Camilo's next task is to help them enter this information into Protector. "It's all going to come together. Weather along with pests, and then the harvest. Expectations are high for this," concludes the sugarcane grower.

For additional reading, please also take a look at our article on renovating sugarcane plantations: soy and sugarcane side by side.

By Luisa Torres