In the cotton-growing regions of Brazil, movement of people and machinery on the farms is intensifying. Harvest time has arrived. It's time to press, bundle, and package the fiber. It's also time to take a look at the results of all the work done during the harvest in terms of productivity and the high standards of the cotton picked. In the quest for quality, embracing technology is a differentiating factor.

Did you know that 62% of MATOPIBAPA's cotton growers use Syngenta Digital tools?

How does cotton technology work?

This is the story of the Zanotto family, who for two decades have helped transform Luís Eduardo Magalhães in western Bahia, Brazil into a veritable "sea of cotton", as the city is widely known. "Although we grow other crops such as soybeans and corn, cotton is already part of the group's DNA. We even have a processing plant," says Roberto Schwartz Costa, Director of the Zanotto Group.

Year in and year out, before planting, the group analyzes the market in order to plan the next harvest. The expectation for the 22/23 crop year, for example, is that the planted area will grow by more than 46%.

This variation is justified and further reinforces the need to incorporate technology into the operation: cotton is a high-investment crop. Everything needs to be very well planned and monitored.

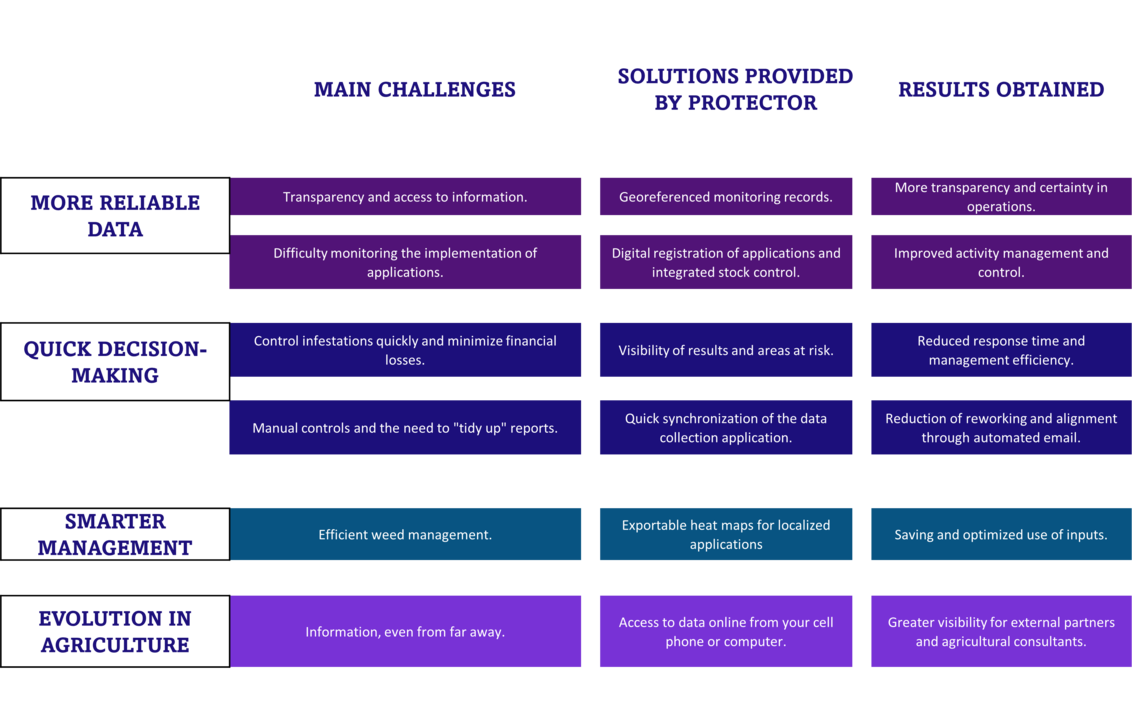

It's for this reason that Zanotto decided to take a step towards going digital and brought Syngenta Digital's technology to the forefront of its farms. "We've been using Cropwise Protector since 2020. The greatest value for us, without a doubt, is the georeferencing of monitoring, which brings transparency and reliability to our operations," emphasizes the director.

Digital monitoring in cotton fields

Until recently, the monitoring carried out by our experts was done on paper and sent to Ricardo Suzuki, the Zanotto group's agronomic consultant, who was initially concerned about the change.

"My greatest concern, when they decided to implement new technology on the farm, was that it would increase the amount of time technicians would have to spend in the fields entering information into the application. However, that didn't happen. It's going very well," admits Suzuki, who also explains that georeferencing has really helped him to understand how the team has been monitoring things and whether the team is following the schedule that has been set.

The data collected in the field by technicians can be accessed by managers so that they can make better decisions. "Since we need things very quickly, decisions need to be precise and that's what monitoring helps us with," adds Roberto, who also mentions two other major benefits of Protector: "application and stock control help a lot. Since everything is posted on the system, everyone is aware of what has been done. I believe it has democratized information. Now everyone is on the same page. It's more difficult for things to get lost now," he says.

Cropwise Protector reports

With Cropwise Protector, once the team has been monitored, the farm management team receives an email report of everything that has been done that day by field technicians. This even saves time, since the team no longer has to transfer information to the computer when they return to the office.

Ricardo is one of the people in the Zanotto group who receives the report. Since he visits the group once a week, the consultant is able to keep up to date, even from a distance, before going out to the fields.

"I work with other producers too. The day before I visit them, I take a look at Protector. It's really made my work easier. I arrive knowing what I'm going to find, what the pest pressure is, especially as the fields are large," says the consultant.

"Protector doesn't replace Ricardo's consultancy work. It complements and serves as a warning to identify problems," adds Roberto.

The next steps for technology in cotton and other crops

In addition to cotton, the Zanotto group, which owns three farms, grows soybeans, corn, and beans, totaling 4,200 hectares. Protector is used to monitor these crops too.

Roberto explains that the next step is to make even greater use of the options offered by the system. "We want to explore images further to help us analyze, identify, and understand soil stains and nematode stains. We've just started and we're going to give it a try, mainly looking for practical solutions for combating weeds, for example, using localized applications. The idea is to start spraying only where there is infestation. We've seen and heard about cases of huge savings on pesticides," he concludes.

Would you like to learn about all the benefits that Cropwise Protector offers? Have a read of this article about the power of NDVI images in Cropwise Protector.

By Luisa Torres